The chemical plant Nortex-Lipetsk is located in the special economic zone of Lipetsk (about 450 km from Moscow along the M4 highway). The plant was launched in 2013 and today is a full-fledged industrial enterprise with a modern production line and its own laboratory.

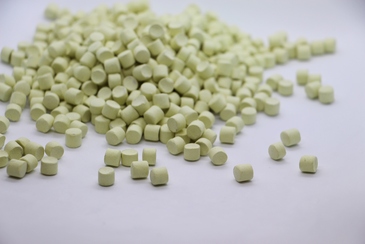

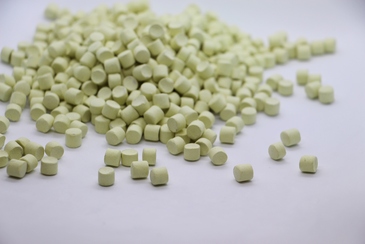

Nortex-Lipetsk produces high-tech polymer-bound additives for tires and rubber products under the trademark Nortgran. The plant's capacity is 1,500 tons Nortgran per year.

These additives have high chemical efficiency, stability and rapid dispersion into compounds. The use of Nortgran in the production of final products reduces the cost of recycling and minimizes the amount of defects. In addition, their advantage is the produced form in the form of granules, which ensures easy weighing and dosing, which allows for automation of the technological process. Thanks to the polymer shell of Nortgran, the product does not form chemical dust and is non-toxic, providing an optimal ecological and safe environment in production.

Content of the main substance

Resorcinol

Polymer binder

SBR

Release form

milky granules

Resorcinol is an ingredient of resorcinol/silica white/formaldehyde adhesion system. It can lead to formation of resorcinol/formaldehyde resin adhesion system for rubber and fabric or steel cord together with formaldehyde donors in processing. The system is suitable to adhesion between various rubber and reinforcing materials such as fibers, glass fibers and metal (such as steel cord).

Read more ∨

Content of the main substance

Zinc Oxide

Polymer binder

SBR

Release form

white granules

Read more ∨

Content of the main substance

Insoluble sulphur

Polymer binder

EPDM

Release form

yellow granules

Vulcanizing agent for natural and synthetic rubber compounds.

Read more ∨

Content of the main substance

N-cyclohexyl-2-benzothiazyl sulfenamide

Polymer binder

SBR

Release form

violet granules

Vulcanization accelerator CBS can lead to long scorching time of rubber compounds, high processing safety and fast vulcanization rate. It can be used alone in low-sulfur vulcanization, and also can be used together with dithiocarbamates or thiurams. Its vulcanizate has excellent properties of anti-ageing and compression set resistance. It can obviously shorten scorching time of rubber compounds together with dithiocarbamates and thiurams. Thioureas have obvious effect on secondary acceleration to CBS, especially in low-sulfur rubber compounds. It can delay scorching and improve processing safety in thiols and thiurams rubber compounds.

Read more ∨

Content of the main substance

Sulphur

Polymer binder

SBR

Release form

orange granules

Sulphur is a vulcanizing agent for natural and synthetic rubber. It is extremely important for light-colored rubber products to use Nortgran S-80/SBR due to excellent dispersion to avoid brown-spot appearance and minimize the defects of vulcanizates.

Read more ∨

Content of the main substance

N-tert.-butyl-2-benzothiazyl sulphenamide

Polymer binder

SBR

Release form

pink granules

Basic accelerator for SBR, with good scorching, fast vulcanization speed, high vulcanization modulus, wide applications.

Read more ∨

Content of the main substance

N,N'-diphenyl guanidine

Polymer binder

SBR

Release form

light-yellow granules

Read more ∨

Content of the main substance

N,N-Dicyclohexyl-2-Benzothiazole Sulfenamide

Polymer binder

SBR

Release form

blue granules

Semi-ultra accelerator for the vulcanisation of natural and synthetic rubbers.

Read more ∨

Content of the main substance

N-(Cyclohexylthio)-phthalimide

Polymer binder

SBR

Release form

green granules

Active ingredient CTP is a vulcanization retarder of nature rubber and diene rubbers, which can unnoticeably prolong total vulcanizing time. It can improve processing safety and not impact properties of vulcanizates combination with sulfenamides or thiazoles. This product can significantly improve the storage stability and high temperature processing safety performance of unvulcanized rubber, fully improve equipments production capacity. It does not cause a contact stain.

Read more ∨

Content of the main substance

Hexamethylene tetramine

Polymer binder

SBR

Release form

grey granules

HEXA is a weak alkaline accelerator for slow vulcanization. Vulcanization reaction started as soon as HEXA was added in, with a slow rate and a high degree of cross-linking of the vulcanizate. Thiols, sulfenamides, thiurams and dithiocarbamates are activators and secondary accelerators to HEXA contained rubber compounds. As a formaldehyde donor, it is especially suitable to adhesion between rubber and metal or steel cord with resorcinol. It can not lead to blooming appearance normally.

Read more ∨

Content of the main substance

Dibenzothiazol disulphide

Polymer binder

SBR

Release form

light-pink granules

MBTS is a general quasi-ultrafast accelerator with excellent processing safety which can be used alone or combined with other accelerators, in addition, MBTS together with activated dithiocarbamates can avoid rubber scorching. Thiurams, dithiocarbamates and aldehyde-amines can activate MBTS. It is a retarder for processing and vulcanizing of CR compounds. It can improve processing safety with ultrafast accelerators. Its vulcanizate has an excellent heat aging resistance.

Read more ∨

Content of the main substance

Zinc dimethyl dithiocarbamate

Polymer binder

EPDM

Release form

beige granules

ZDMC is an ultrafast accelerator for natural and synthetic rubber such as SBR, NBR, EPDM. Addition of thiurams and thiazoles can delay initial vulcanization and improve processing safety. Compared to ZDBC, ZDEC and ZDPC, ZDMC has longer scorching time and shorter total vulcanization time. Alkaline accelerators can acvivate ZDMC. A little of ZDMC can be secondary accelerators for thiols or thiurams. It can improve tensile strength and resilience of its vulcanizate. Combined with antioxidant It can improve heat resistance for NR and IR.

Read more ∨

Content of the main substance

Tetrame thylthiuram disulphide

Polymer binder

EPDM

Release form

white granules

TMTD can extremely accelerate vulcanization rate of natural and synthetic rubber and has good scorching safety. It almost does not affect degree of cross-linking but delay vulcanization: only lower scorching rate and extend total vulcanization time if thiols or sulfenamides is added in. Alkaline accelerators such as aldehyde-amines and guanidines can activate TMTD. It is a primary accelerator with sulfur, a secondary accelerator with thiazoles and a vulcanizator in sulfurless vulcanization. Sulfurless or low-sulfur vulcanization can provide excellent heat-proof ageing properties for vulcanizates.

Read more ∨

Content of the main substance

Dipen tamethylene thiuram tetrasulfide

Polymer binder

EPDM

Release form

beige granules

DPTT accelerates vulcanization rate of natural rubber and synthetic rubber and has high scorching safety. It can be combined with thiols and sulfenamides accelerators as an activator and secondary accelerator. A little of DPTT combined with thiurams accelerator can improve ageing-resistant performance of vulcanizates.

Read more ∨

Content of the main substance

Dibenzothiazol disulphide

Polymer binder

EPDM

Release form

green or beige granules

MBTS is a general quasi-ultrafast accelerator with excellent processing safety which can be used alone or combined with other accelerators, in addition, MBTS together with activated dithiocarbamates can avoid rubber scorching. Thiurams, dithiocarbamates and aldehyde-amines can activate MBTS. It is a retarder for processing and vulcanizing of CR compounds. It can improve processing safety with ultrafast accelerators. Its vulcanizate has an excellent heat aging resistance.

Read more ∨

Content of the main substance

Benzothiazyl-2-sulphene morpholide

Polymer binder

EPDM

Release form

beige granules

MBS scorch the rubber quite a long time, Curing process is quite safe and very complete. the low sulfur vulcanization can be used alone , also can use with dithiocarbamate or thiuram accelerator. The vulcanized rubber has good heat aging properties and good compression set and the scorch time of rubber will be significantly reduced. In the low-sulfur, sulfur-containing Rubber alcohols and thiuram accelerator, MBS-80 can delay scorch. Uses: tire tread, carcass, hose, belt, cable and rubber shoes and other rubber products.

Read more ∨

Content of the main substance

Zinc Oxide

Polymer binder

EPDM

Release form

white granules

Read more ∨

Content of the main substance

Resorcinol

Polymer binder

EPDM

Release form

milky granules

In direct bonding compounds, e.g. for the bonding system resorcinol/formaldehyde/silica.

Content of the main substance

N-(Cyclohexylthio)-phthalimide

Polymer binder

EPDM

Release form

beige granules

Active ingredient CTP is a vulcanization retarder of nature rubber and diene rubbers, which can unnoticeably prolong total vulcanizing time. It can improve processing safety and not impact properties of vulcanizates combination with sulfenamides or thiazoles. This product can significantly improve the storage stability and high temperature processing safety performance of unvulcanized rubber, fully improve equipments production capacity. It does not cause a contact stain.

Read more ∨

Content of the main substance

N-tert.-butyl-2-benzothiazyl sulphenamide

Polymer binder

EPDM

Release form

beige granules

TBBS can lead to long scorching time of rubber compounds, high processing safety and fast vulcanization rate. It can be used alone in low-sulfur vulcanization and can also be combined with dithiocarbamates or thiurams accelerators to improve anti-aging property and modulus of its vulcanizate. Combination with dithiocarbamates and thiurams accelerators can lower vulcanization rate of rubber compounds significantly. Thioureas accelerators have obvious secondary acceleration to TBBS, especially in low-sulfur rubber compounds. TBBS can delay scorching in rubber compounds contained thiols and thiurams accelerators.

Read more ∨

Content of the main substance

N-cyclohexyl-2-benzothiazyl sulfenamide

Polymer binder

EPDM

Release form

beige granules

Vulcanization accelerator CBS can lead to long scorching time of rubber compounds, high processing safety and fast vulcanization rate. It can be used alone in low-sulfur vulcanization, and also can be used together with dithiocarbamates or thiurams. Its vulcanizate has excellent properties of anti-ageing and compression set resistance. It can obviously shorten scorching time of rubber compounds together with dithiocarbamates and thiurams. Thioureas have obvious effect on secondary acceleration to CBS, especially in low-sulfur rubber compounds. It can delay scorching and improve processing safety in thiols and thiurams rubber compounds.

Read more ∨

Content of the main substance

Hexamethylene tetramine

Polymer binder

EPDM

Release form

beige granules

HEXA is a weak alkaline accelerator for slow vulcanization. Vulcanization reaction started as soon as HEXA was added in, with a slow rate and a high degree of cross-linking of the vulcanizate. Thiols, sulfenamides, thiurams and dithiocarbamates are activators and secondary accelerators to HEXA contained rubber compounds. As a formaldehyde donor, it is especially suitable to adhesion between rubber and metal or steel cord with resorcinol. It can not lead to blooming appearance normally.

Read more ∨

Content of the main substance

Sulphur

Polymer binder

EPDM

Release form

yellow granules

Sulphur is a vulcanizing agent for natural and synthetic rubber. It is extremely important for light-colored rubber products to use Nortgran S-80 due to excellent dispersion to avoid brown-spot appearance and minimize the defects of vulcanizates.

Read more ∨

Content of the main substance

Insoluble sulphur

Polymer binder

EPDM

Release form

yellow granules

Vulcanizing agent for natural and synthetic rubber compounds.

Read more ∨

Content of the main substance

Zinc dibutyl dithiophosphate

Polymer binder

EPDM

Release form

beige granules

Non-staining special accelerator for the rapid vulcanization of diene rubbers.

Read more ∨

Content of the main substance

Dithiodi morpholine

Polymer binder

EPDM

Release form

beige granules

DTDM is a free sulfur donor under normal curing conditions. Compared to sulfur, it leads to mono- and di-sulfur cross-links and imparts excellent heat ageing properties. A blooming phenomenon will not occur, which is different from TMTD. However, acid ingredient in formula will lead to premature decomposition of DTDM and lower scorch safety. It applies to rubber compounds of low compression set and excellent heat aging properties.

Read more ∨